Water jet

For the production of customized flat gaskets, such as gasket rings or blanks, we at Rehm resort to various manufacturing processes - including waterjet cutting. This method allows precise cuts and complex geometries in the shortest possible time, regardless of whether a single part or an entire gasket series is to be created.

How waterjet cutting works

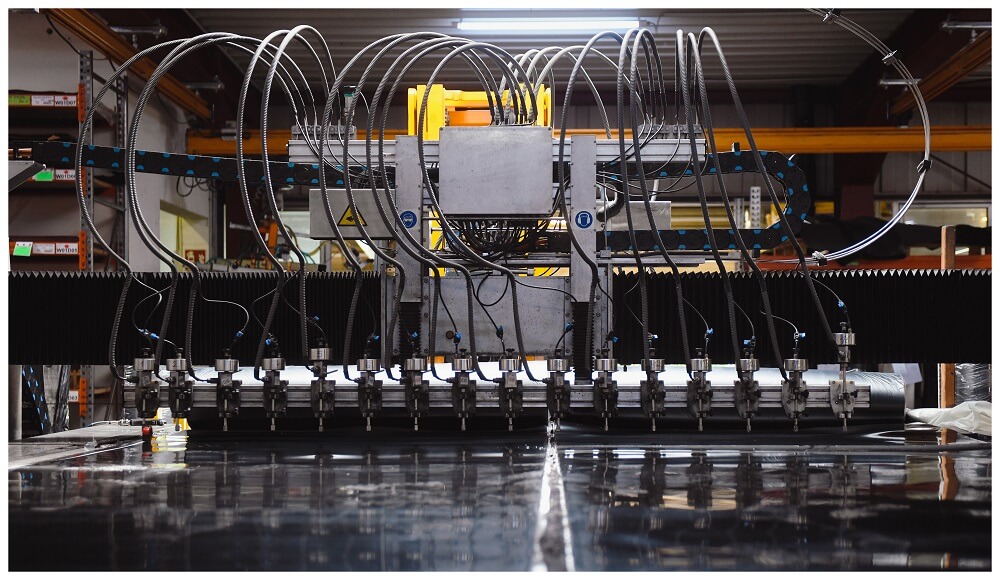

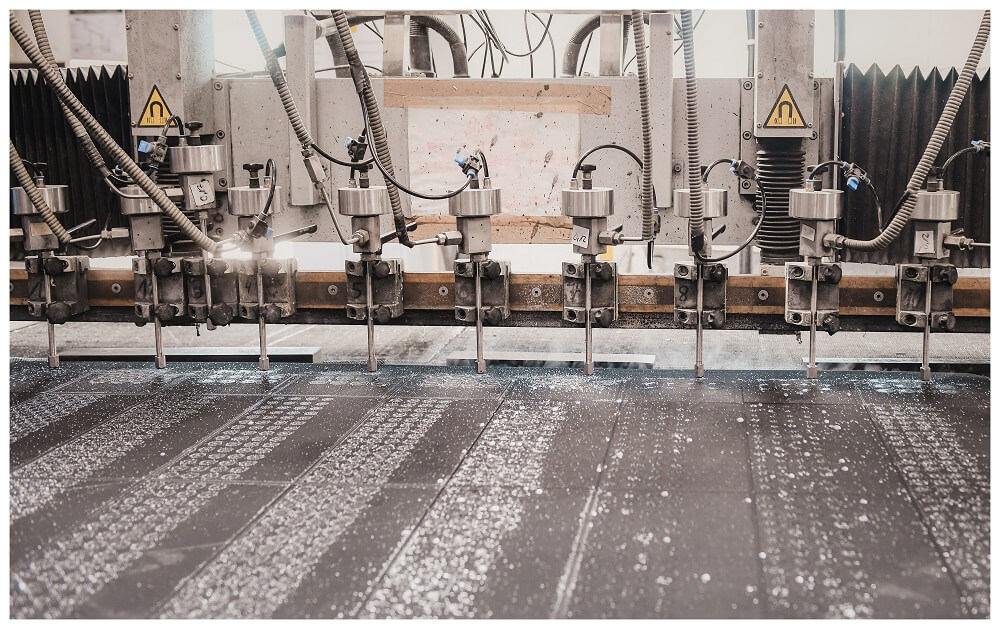

Waterjet cutting is a non-thermal cutting method. It uses pure water to cut almost all materials available to us. This method uses ordinary tap water that is filtered and pressurized in an ultra-high pressure pump. At the waterjet cutting heads, the pressure is converted into velocity through the use of an orifice plate. The resulting waterjet produces identical flat gaskets with a minimum of material waste - regardless of the number of pieces.

The advantages of waterjet cutting

Our waterjet cutting machines allow the highest precision in cutting two-dimensional contours even in small dimensions. This technology is suitable, for example, for any seals, sleeves, micro-seals, standard seals as well as blanks of all kinds. With up to 20 cutting heads, our waterjet cutting systems produce all batch sizes from single-part production to large series. We can produce efficiently, cost-effectively and in a material-saving manner. Furthermore, waterjet cutting enables us to process material sizes of up to 3,000 millimeters in width and 6,000 millimeters in length as well as a thickness of up to 50 millimeters. We can also cut the sealing materials you provide to us on a contract basis.

Other advantages of waterjet cutting at a glance:

- Fast production - Thanks to our multi-head waterjet cutting machines, we can realise short production times, especially for high quantities as well as large seamless seals.

- Very high cutting precision - A pure water jet enables thin cuts of 0.1-0.25 mm and thus ensures the lowest tolerances.

- Versatile - With the help of our waterjet cutting systems, we can cut a wide variety of materials and shapes.

In addition, waterjet cutting enables good material utilisation and a high nesting density.

Possible materials for waterjet technology:

As experts in gaskets and flat gaskets, we at Rehm have a wide range of different materials at our disposal for this purpose. Depending on the application, some of the materials are more suitable than others. In our Materials section, you will find further information on the individual sealing materials.

All materials without metal inserts are suitable for waterjet cutting. These include elastomers, silicones, rubbers, plastics, fibrous materials, foamed materials and others. We will be happy to inform you about the optimum material selection.

Our service for you - customised waterjet-cut seals

Benefit from our expertise in waterjet technology and the resulting attractive price-performance ratio. With our waterjet cutting systems, we can produce customised flat gaskets for you.

Get intouch with us. Together we can discuss your next sealing project.