Frenzelit®-Dichtungen

Frenzelit® ist der Oberbegriff für mehrere Dichtungsmaterialien der Frenzelit GmbH. Darunter fallen eine Reihe verschiedener Materialqualitäten für unterschiedliche Einsatzbereiche, insbesondere für allgemeine Industrieanwendungen.

Verfügbare Frenzelit®-Qualitäten bei der Rehm Dichtungen Ehlers GmbH

Bei uns erhalten Sie Frenzelit®-Dichtungen als Rollen- und Plattenware für den weiteren Zuschnitt zu Dichtungen. Die technischen Daten beziehen sich auf eine Materialdicke von 3,0 mm. Frenzelit-Dichtungsmaterialien gibt es in unterschiedlichen Qualitäten, die sich in Untergruppen sortieren lassen – abhängig vom verwendeten Basismaterial.

Isoplan GREENLINE – Frenzelit®

Die Isoplan GREENLINE enthält hervorragend hochtemperaturbeständiges Dichtungsmaterial, das im Bereich der Wärmetechnik, des Brandschutzes und als Schalldämpfung einsetzbar ist. Basis der drei Qualitäten Isoplan 750, Isoplan 1000 und Isoplan 1100 sind biolösliche Mineralfasern. Sie besitzen einen niedrigen Wärmeleitwert.

Frenzelit® Isoplan 750 GREENLINE

Das Material zeichnet sich durch einen sehr guten Wärmeisolationswert aus und ist dauerhaft bei Temperaturen bis 750° C einsetzbar.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] | DIN 28090-2 | 0,93 |

| Zusammendrückung [%] | ASTM F 36 K | 7 |

| Rückfederung [%] | ASTM F 36 K | 58 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 7,5 |

| Wärmeleitwert, 400° C Mittelwert [W/(m∙K)] | 0,13 |

Frenzelit® Isoplan 1000 GREENLINE

Diese Qualität zeichnet sich durch einen sehr niedriger Wärmeleitwert aus. Dadurch ist eine hervorragende Hitzeisolation bei dauerhaften Temperaturen bis 1000° C gegeben.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] | DIN 28090-2 | 0,94 |

| Zusammendrückung [%] | ASTM F 36 K | 8 |

| Rückfederung [%] | ASTM F 36 K | 61 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 8,0 |

| Wärmeleitwert, 400° C Mittelwert [W/(m∙K)] | 0,13 |

Novapress – Frenzelit®

Der Werkstoff Novapress gehört zu der Produktfamilie elastomergebundener Dichtungsmaterialien auf Basis hochwertiger Aramidfasern sowie spezieller Funktionsfüllstoffen.

Novapress liegt uns in unterschiedlichen Qualitäten (Novapress 850, Novapress Universal, Novapress Basic, Novapress flexibel/815, Novapress Multi II, Novapress Multi II EG) vor und deckt nahezu alle Standardanwendungen ab. Grundsätzlich weisen Novapress-Materialien eine Breite an chemischen Beständigkeiten, wie beispielsweise gegenüber Kältemitteln, Gasen oder Kraftstoffen, auf. Darüberhinaus verfügen die einzelnen Novapress-Qualitäten über verschiedenste Zulassungen, weshalb sie als universeller Werkstoff in der Dichtungstechnik gelten. Jedoch weist jede Qualität spezielle Eigenschaften auf, die das jeweilige Dichtungsmaterial für ausgewählte Anwendungen begünstigen.

Frenzelit® Novapress® 850

Novapress 850, welches auch als Novaform 2300 bekannt ist, vereint die hervorragende Anpassungsfähigkeit von Elastomerdichtungen mit der mechanischen Stabilität klassischer Faserstoffdichtungen. Folglich bietet sich der Einsatz von Flachdichtungen aus Novapress 850 in all denen Bereichen an, wo weder Elastomer- noch Faserstoffdichtungen die optimale Dichtungslösung darstellen.

Das Material ist sehr anpassungsfähig und mechanisch stabil, wodurch auch bei einer sehr geringen Flächenpressung eine extrem geringe Leckage gewährleistet ist. Dichtungen aus Novapress® 850 sind für den Lebensmittelbereich (FDA, EG 1935/2004) und die Wasserversorgung (Trinkwasserzulassung gemäß Elastomerleitlinie (ELL), W270) sowie die Gasversorgung (DVGW, VP 401) zugelassen. Darüberhinaus bietet sich Novapress 850 für Bauteile mit ungleichmäßig bestehenden Flächenpresseungen an, wie z.B. in Deckel- und Gehäuseabdichtungen von Getrieben oder Pumpen.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] | DIN 28090-2 | 1,4 |

| Zusammendrückung [%] | ASTM F 36 J | 39 |

| Rückfederung [%] | ASTM F 36 J | 60 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 5 |

Frenzelit® Novapress® Basic

Der Werkstoff Novapress basic ist vor allem für Anwendungen im mittleren Druck- und Temperaturbereich dank guter Medienbeständigkeit und Druckstandsfestigkeit sowie niedriger Gasleckage geeignet. Aus diesem Grund haben Flachdichtungen aus Novapress basic ein weit gefächertes Anwendungsspektrum und können z.B. im Maschinen-, Anlagen- und Schiffsbau sowie für Rohrleitungen in der Gas- und Wasserversorgung eingesetzt werden.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] bei 3 mm Dicke | DIN 28090-2 | 1,7 |

| Zusammendrückung [%] | ASTM F 36 J | 6 |

| Rückfederung [%] | ASTM F 36 J | 55 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 6 |

Frenzelit® Novapress® flexibel/815

Das sehr anpassungsfähiges Material weist eine hohe Öl- und Mineralstoffbeständigkeit auf.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] bei 2 mm Dicke | DIN 28090-2 | 1,5 |

| Zusammendrückung [%] | ASTM F 36 K | 100 |

| Rückfederung [%] | ASTM F 36 K | 64 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 9 |

Frenzelit® Novapress® multi II

Flachdichtungen aus Novapress multi II gelten, aufgrund der Material-Kombination aus Aramidfasern, Graphit, speziellen Funktionsfüllstoffen, die mit NBR gebunden werden, als optimierte Dampfdichtungen. Vor allem durch den Einsatz von Graphit sind Dichtungen bzw. Flachdichtungen aus Novapress multi II für den Einsatz mit Dampf, Heizöl, Verschraubungen mit Torsionsbelastung sowie unter Wechsellast geeignet. Der Temperatureinsatzbereich von Novapress multi II liegt zwischen -100 bis +250 Grad Celsius, weshalb das Dichtungsmaterial als hoch temperaturbeständig angesehen werden kann.

Der Werkstoff ist nach BAM geprüft und zugelassen nach BS7531 Grade X, DVGW, GL sowie TA Luft.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] bei 3 mm Dicke | DIN 28090-2 | 1,6 |

| Zusammendrückung [%] | ASTM F 36 J | 7 |

| Rückfederung [%] | ASTM F 36 J | 60 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 12 |

Frenzelit® Novapress® multi II EG

Dieses Material ist eine Dampfdichtung mit Verstärkung aus Edelstahlgewebe und hervorragend beständig in Heißöl und Dampf.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] bei 3 mm Dicke | DIN 28090-2 | 1,7 |

| Zusammendrückung [%] | ASTM F 36 K | 7 |

| Rückfederung [%] | ASTM F 36 K | 64 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 17 |

Frenzelit® Novapress® universal

Novapress Universal gilt aufgrund der unterschiedlichsten Anwendungsbereiche als Klassiker der elastomergebundenden Faserstoffdichtungen. Auch für höhere technische Anforderungen bis weit in den Temperaturgrenzbereich finden Flachdichtungen aus Novapress Universal Ihren Einsatz.

Das mechanisch äußerst robust Material ist chemisch gut beständig und auch für anspruchsvolle Anwendungen in gasförmigen und flüssigen Medien zugelassen.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] bei 3 mm Dicke | DIN 28090-2 | 1,8 |

| Zusammendrückung [%] | ASTM F 36 J | 6 |

| Rückfederung [%] | ASTM F 36 J | 60 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 10 |

Novatec – Frenzelit®

Novatec PREMIUM XP ist für anspruchsvolle Anwendungsanforderungen konzipiert und enthält einen hohen Anteil an Graphit.

Frenzelit® Novatec® PREMIUM XP

Diese faserverstärkte Graphitdichtung weist einen sehr hohen Graphitanteil auf und ist chemisch außerordentlich beständig.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] bei 2 mm Dicke | DIN 28090-2 | 1,74 |

| Zusammendrückung [%] | ASTM F 36 K | 6 |

| Rückfederung [%] | ASTM F 36 K | 60 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 18 |

Novaphit – Frenzelit®

Dichtungsmaterialien der Produktfamilie Novaphit vom Hersteller Frenzelit gelten als hochwertige Flachdichtungsmaterialien aus expandiertem Graphit. Novaphit Dichtungen zeichnen sich vor allem durch eine universelle chemische Beständigkeit, hervorragende Anpassungsfähigkeiten an Flanschunebenheiten sowie Unempfindlichkeiten gegenüber Wechsellasten aus. Weiterhin können Novaphit Dichtungen im Temperaturbereich von -200 bis +550 Grad Celsius eingesetzt werden und sind somit als temperaturbeständige bzw. hitzebeständige Dichtungen anzusehen. Aus diesem Grund lassen sich Novaphit Flachdichtungen als langlebig und zuverlässig auch in Anwendungsgrenzbereichen charakterisieren.

Zu der Produktfamilie Novaphit gehören bei uns, der Rehm Dichtungen Ehlers GmbH, die beiden Dichtungsmaterialien Novaphit SSTC und SSTCTA-L.

Frenzelit® Novaphit® SSTC

Das Dichtungsmaterial Novaphit SSTC besteht aus expandiertem Graphit mit einer Einlage aus säurebeständigem Streckmetall. Insbesondere durch die Reinheit des expandierten Graphits kann eine herausragende Medienbeständigkeit sowie höchste Sicherheitsreserven bei Lastwechseln garantiert werden. Die säurebeständige Einlage von novaphit SSTC führt wiederum zu einem geringen Leckageverhalten der eingesetzten Flachdichtung.

Dichtungen aus Frenzelit® Novaphit® SSTC lassen sich durch folgende Eigenschaften charakterisieren. Zum Einen sorgen sie für eine optimierte Verteilung der Flächenpressung und zum anderen optimieren sie dank rückfedernden Eigenschaften das Dichtverhalten.

Das Dichtungsmaterial ist geprüft nach BAM und weiterhin zertifiziert nach DVGW, Firesafe und GL.

Aus diesem Grund ist Novaphit SSTC als Dichtungsmaterial für nahezu alle Anwendungsbereiche eine intelligente Dichtungslösung.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] bei 3 mm Dicke | DIN 28090-2 | 1,25 |

| Zusammendrückung [%] | ASTM F 36 J | 38 |

| Rückfederung [%] | ASTM F 36 J | 15 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 7 |

Frenzelit® Novaphit® SSTC TA-L

Die Qualität Novaphit SSTCTA-L setzt sich aus einer Kombination von expandiertem Graphit und einer Einlage aus säurebeständigem Chrom-Nickel-Stahl zusammen. Darüber hinaus verfügt Novaphit SSTCTA-L über eine Innenimprägnierung, die eine maßgebliche Reduktion des Leckageverhaltens der Flachdichtung hervorruft. Dichtungen bzw. Flachdichtungen aus Novaphit SSTCTA-L gelten als hochwertig im Sinne der TA Luft (TA-L) und ist zusätzlich geprüft bzw. zugelassen nach BAM, Blow-out VDI 2200, DVGW, Firesage, GL und VP 401

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] bei 3 mm Dicke | DIN 28090-2 | 1,25 |

| Zusammendrückung [%] | ASTM F 36 J | 40 |

| Rückfederung [%] | ASTM F 36 J | 15 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 7 |

Novaform – Frenzelit®

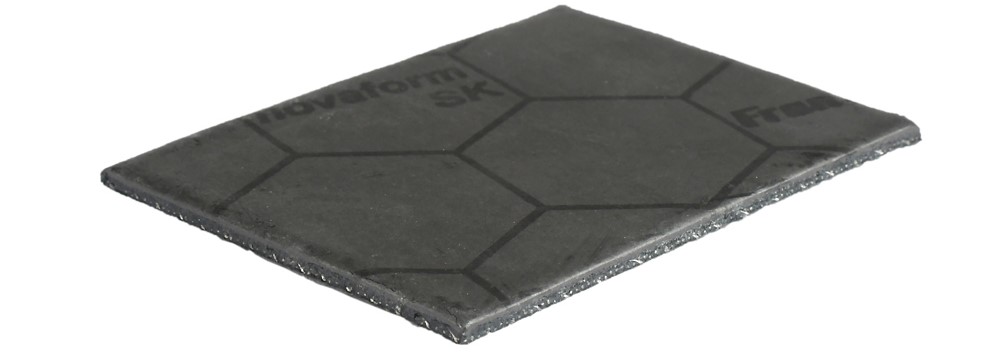

Dichtungen in Frenzelit®-Novaform-Qualität Novaform SK sind speziell für den Einsatz in der industriellen Abgasumgebung geeignet, da sie sehr gute thermische sowie mechanische Belastbarkeiten aufweisen.

Frenzelit® Novaform® SK

Die Weichstoffmatrix dieser Qualität ist mit einer Drahteinlage in Spitzköperwebart verstärkt und dadurch mechanisch äußerst robust. Zudem ist das Material bis 600° C temperaturbeständig und liefert eine zuverlässige Langzeitperformance.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] bei 3 mm Dicke | DIN 28090-2 | 1,20 |

| Zusammendrückung [%] | ASTM F 36 K | 20 |

| Rückfederung [%] | ASTM F 36 K | 35 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 25 |

Novaflon – Frenzelit®

Novaflon basiert auf expandiertem PTFE (Polytetrafluorethylen). Da dieses Material in den Qualitäten Novaflon 100 und Novaflon 300 gegen die meisten Säuren und Laugen unempfindlich ist, ist es besonders gut für den Einsatz in der chemischen Industrie geeignet. Auch in der Lebensmittel- und pharmazeutischen Industrie ist Novaflon verwendbar.

Frenzelit® Novaflon® 100

Die Qualität besteht aus strukturiertem PTFE, gefüllt mit Mikrohohlglaskugeln. Sie ist universell beständig gegen fast alle Chemikalien im gesamten pH-Bereich und passt sich optimal den Dichtflächen an.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] bei 2 mm Dicke | DIN 28090-2 | 1,5 |

| Zusammendrückung [%] | ASTM F 36 K | 35 |

| Rückfederung [%] | ASTM F 36 K | 30 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 15 |

Frenzelit® Novaflon® 300

Frenzelit® Novaflon® 300 besteht aus mit Silikat gefülltem strukturiertem PTFE. Das Material zeichnet sich durch eine hervorragende Medienbeständigkeit, auch in konzentrierten Säuren und Laugen (bis 85° C), aus. Dadurch ist Novaflon® 300 besonders für den Einsatz in der Prozessindustrie geeignet.

Technisches Datenblatt:

Eigenschaften:

| Dichte [g/cm³] bei 2 mm Dicke | DIN 28090-2 | 2,10 |

| Zusammendrückung [%] | ASTM F 36 K | 7 |

| Rückfederung [%] | ASTM F 36 K | 45 |

| Zugfestigkeit quer [N/mm³] | DIN 52910 | 15 |

Abgrenzungen von Frenzelit®-Dichtungen

Im Rahmen der unterschiedlichen Qualitäten, lassen sich drei verschiedene Obergruppen von Dichtungsmaterialien vom Hersteller Frenzelit differenzieren. Die meisten, bei uns erhältlichen Qualitäten, sind der Gruppe der Faserstoffe zuzuordnen. Hierunter fallen die verschiedenen Novapress-Materialien, wie z.B. Novapress 850, Novapress Basic oder Novapress Universal. Sie alle beruhen auf der Zusammensetzung synthetischer Aramidfasern, welche mit NBR gebunden werden.

Die maximale Einsatztemperatur der eben genannten Faserstoffe liegt bei ca. 150° C. Dies ist darin begründet, da sich ab einer höheren Einsatztemperatur das gebundene NBR auflöst und sich somit Schraubenkraftverluste ergeben. Für Anwendungen mit höheren Temperaturen eignen sich PTFE-basierte bzw. Graphit-basierte Dichtungsmaterialien. PTFE als Werkstoff gilt als nahezu chemisch universell einsatzbar und weist eine hohe Anpassungsfähigkeit auf. Im Vergleich zu den Faserstoffen können PTFE Dichtungen im Temperaturbereich zwischen -270°C bis maximal +260°C eingesetzt werden und zählen somit zu den hitzebeständigen Dichtungen. Vom Hersteller Frenzelit führen wir im Bereich der PTFE-basierten Dichtungsmaterialien unterschiedliche Novaflon®-Qualitäten, die sich lediglich auf Basis unterschiedlich verwendeter Füllstoffe unterscheiden.

Einen noch höheren Einsatztemperaturbereich ermöglichen Dichtungen aus Graphit. Der Temperaturbereich liegt zwischen -270° C und +550° C. Auch sie werden bei uns, der Rehm Dichtungen Ehlers GmbH, als hitzebeständige Dichtungen verstanden. Bei uns erhalten Sie vom Hersteller Frenzelit als Graphit-Dichtungsmaterial die Novaphit® SSTC und Novaphit SSTC-TAL.

Sie haben Fragen oder möchten sich kostenlos beraten lassen?

Kontaktieren Sie uns gerne – wir helfen Ihnen! Unser engagiertes Team steht Ihnen stets zur Verfügung, um Ihre Fragen zu beantworten.

Anwendungsgebiete von Frenzelit®-Dichtungen

Dichtungen aus Frenzelit®-Dichtungsqualitäten werden insbesondere im industriellen Bereich sowie in der Lebensmittelindustrie eingesetzt: Als Dichtungsmaterial in Chemieanlagen, in der Papierherstellung, aber auch in der Offshore-Industrie und dem Schiffsbau und weiteren Einsatzgebieten.

Ob Frenzelit®-Materialien auch für Ihre Zwecke geeignet ist, beantworten wir Ihnen gern. Kontaktieren Sie dazu unseren Kundenservice und lassen Sie sich umfassend beraten.

FAQ

Was sind Frenzelit-Dichtungen?

Können Frenzelit Dichtungen auch selbstklebend ausgestattet werden?

In welchen Formen können Frenzelit-Qualitäten bei Rehm Dichtungen bezogen werden?

Zu den Faserstoffdichtungen zurückkehren