Graphit-Dichtungen

Bei Graphit Dichtungen handelt es sich um eine eigene Gruppe an Dichtungsmaterialien, welche sich vor allem aufgrund des breiten Temperaturbereichs von der Gruppe der Faserstoffe und den Elastomeren abgrenzt. Graphitdichtungen eignen sich für den Einsatz bei Temperaturen im Bereich von -240° C bis +550° C, weshalb Graphitdichtungen sowohl als kälteflexibel als auch als Hochtemperaturdichtungen gelten. Aus diesem Grund verfügt das Dichtungsmaterial über besonders hervorragende thermische Eigenschaften, wodurch dieser Werkstoff in den unterschiedlichsten Industrien eingesetzt wird. Darüber hinaus verfügt das Dichtungsmaterial über viele positive Eigenschaften, wie z.B. eine gute Wärmeleitfähigkeit und eine Vielzahl an Beständigkeiten gegenüber diversen Medien.

Verfügbare Graphit-Materialien bei der Rehm Dichtungen Ehlers GmbH

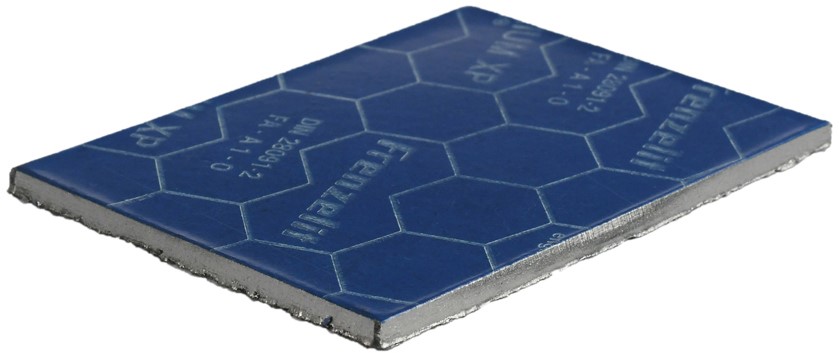

Graphit als Dichtungsmaterial liegt uns, der Rehm Dichtungen Ehlers GmbH, in unterschiedlichen Varianten vor. Da Graphit ein sehr empfindlicher Werkstoff ist, kommt er meist in verstärkter Form, in Kombination mit Metalleinlagen, zum Einsatz. Die einfachste Art, um den Werkstoff zu verstärken sind Graphitdichtungen mit einer Glattblecheinlage. Die Verstärkung erhöht die Festigkeit der Flanschdichtung. Als weitere Ausführung sind wir im Besitz von Graphitdichtungen mit Spießblech. Hierbei werden die mit Nadelwerkzeugen hergestellten Spießbleche beidseitig auf die Graphitfolien aufgewalzt. Abschließend verfügen wir über Graphitdichtungen mit Streckmetalleinlage. Dies sorgt für höchste Druck- und Temperatureigenschaften. Eine exzellente Medienbeständigkeit und hohe Sicherheitsreserven auch bei Wechsellast zeichnen diese Qualität aus.

Graphitqualitäten

Graphit mit Spießblech

Technisches Datenblatt:

Graphit mit Glattblech

Technisches Datenblatt:

Graphit pur

Technisches Datenblatt:

Der Hersteller Frenzelit verfügt zudem über Graphitqualitäten mit einer Streckmetalleinlage, aus denen wir ebenfalls Ihre Flach- oder Flanschdichtung fertigen können. Die bei uns am Lager geführten Frenzelit-Graphit-Qualitäten sind die Werkstoffe Novaphit SSTC sowie Novaphit SSTC TA-L, die beide zur Novaphit-Werkstoffreihe gehören. Beide Materialien bestehen aus einem hochwertig expandierten Graphit kombiniert mit einer säurebeständigen Streckmetalleinlage.

Die Eigenschaften von Graphit als Dichtungsmaterial

Die Grundlage der Dichtungen aus Graphit sind großflockige Naturgraphite, die mithilfe von mechanischen, chemischen und thermischen Reinigungsverfahren weiterverarbeitet werden. Daraus resultieren die wesentlichen Eigenschaften der Endprodukte. Durch den Einsatz von oxidierenden Säuregemischen findet die Erzeugung von Graphiteinlagerungsverbindungen statt. Diese Einlagerungsverbindungen lassen sich wiederum mittels schockartiger Erwärmung auf hohe Temperaturen expandieren. Das Expandat wird anschließend mit mechanischem Druck und thermischen Behandlungsschritten zum Endprodukt verpresst.

Graphit als Dichtungsmaterial vereint eine Vielzahl an positiven Eigenschaften, weshalb es sich als vielseitig einsetzbarer Dichtungswerkstoff in den unterschiedlichen Industrien bewährt hat. Hervorzuheben sind vor allem die thermischen Eigenschaften des Werkstoffs. Graphit Dichtungen verfügen über eine hohe Temperaturstabilität sowie eine gute Wärmeleitfähigkeit. Das begründet vor allem, dass unter Temperatureinfluss keine Versprödung, Gefügeänderung oder Abspaltung von Bestandteilen des Materials stattfindet. Somit kann ein Kriechen oder Fließen der Flanschdichtung ausgeschlossen werden. Der Einsatztemperaturbereich von Flachdichtungen liegt je nach Reinheit zwischen -240° C und +550° C. Aus diesem Grund sind Graphitdichtungen der Gruppe der Hochtemperaturdichtungen zuzuordnen.

Neben den genannten thermischen Eigenschaften verfügen Dichtungen aus Graphit über sehr gute chemische Beständigkeiten. Als Folge lässt sich festhalten, dass der Einsatz von Flachdichtungen aus diesem Werkstoff gegenüber einer Vielzahl unterschiedlichster Medien bei einem weiten Temperaturbereich möglich ist. Dementsprechend kann von einer weitgehend universellen chemischen Beständigkeit, beinahe auf dem Niveau von PTFE ausgegangen werden. Somit eignen sich Graphit Dichtungen im Umgang mit aggressiven Medien, wie z.B. Lösemitteln, Säuren, Laugen und Kühlmitteln, Heiß- bzw. Abgasen sowie Wärmeträgerölen. Da das Dichtungsmaterial über eine erhöhte Dampfbeständigkeit verfügt, kann der Werkstoff zur Abdichtung in Rohrleitungen und Kesseln verwendet werden. Grundsätzlich kann von einer Alterungsbeständigkeit ausgegangen werden. Jedoch führt die unvermeidliche Oxidation unter höheren Temperaturen dazu, dass die Langzeiteignung der Flanschdichtung aus diesem Werkstoff beeinträchtigt wird.

Des Weiteren verfügen Dichtungen aus Graphit gute plastische und elastische Verformbarkeiten, was dazu führt, dass Unebenheiten und Rauheiten des Flansches ausgeglichen werden können. Dies ist auch bei hohen Betriebsdrücken, wie z.B. bei dem Einsatz in Armaturen und Schaugläser, gewährleistet. Somit sind Dichtungen aus diesem Werkstoff nicht nur flexibel gegenüber niedrigen Temperaturen, sondern weisen auch eine nahezu unerreicht hohe Anpassungsfähigkeit auf. Es gilt als Tatsache, dass das Dichtungsmaterial auch unter höheren Temperaturen ein sehr gutes mechanisches Verhalten besitzt.

Des Weiteren verfügen Dichtungen aus Graphit gute plastische und elastische Verformbarkeiten, was dazu führt, dass Unebenheiten und Rauheiten des Flansches ausgeglichen werden können. Dies ist auch bei hohen Betriebsdrücken, wie z.B. bei dem Einsatz in Armaturen und Schaugläser, gewährleistet. Somit sind Dichtungen aus diesem Werkstoff nicht nur flexibel gegenüber niedrigen Temperaturen, sondern weisen auch eine nahezu unerreicht hohe Anpassungsfähigkeit auf. Es gilt als Tatsache, dass das Dichtungsmaterial auch unter höheren Temperaturen ein sehr gutes mechanisches Verhalten besitzt.

Letztlich ist die gute technische Dichtheit bei geringer Flächenpressung anzuführen, was zu einer ausgezeichneten Dichtleistung führt und den Werkstoff zu einer Verwendung als Dichtungsmaterial prädestiniert.

Nachtteilig sind hingegen die eher geringeren mechanischen Zug- und Biegeeigenschaften, welche allerdings durch den Einsatz unterschiedlicher Metalleinlagen verbessert werden können. Die Kombination von Graphit mit Metallverstärkungen hat einen signifikanten Einfluss auf die Verbesserung der Dichteigenschaften, das Leckageverhalten sowie die eben genannten Zug- und Biegebeanspruchungen.

Die Vorteile und Materialeigenschaften von Graphit auf einen Blick

Flach- und Flanschdichtungen aus Graphit zeichnen sich primär durch folgende Vorteile aus:

- Auch unter hohen Temperaturbeanspruchungen langzeitstabiles Kompressions- und Rückfederungsverhalten

- Gute Alterungsbeständigkeit

- Sehr gute chemische Beständigkeit gegenüber einer Vielzahl an unterschiedlichsten Medien

- Sehr gute thermische Eigenschaften (-240° C bis zu +550° C)

- Hohe Anpassungsfähigkeit an Dichtflächenunebenheiten

Zusammengefasst handelt es sich bei Graphit Dichtungen um eine technisch überlegende Produktlösung, die eine dauerhafte Anwendungslösung, insbesondere bei Einsätzen mit höheren Temperatureinflüssen, darstellt. Dies erhöht die Anlagensicherheit und leistet einen nachhaltigen Beitrag in Bezug auf Kosteneinsparungen.

Anwendungsbereiche von Graphit Dichtungen

Aufgrund der beschriebenen universellen chemischen Beständigkeit sowie den thermischen Eigenschaften des Materials, gelten Graphitdichtungen als exzellentes Dichtungsmaterial und bieten vielseitige Einsatzmöglichkeiten in den unterschiedlichsten Industrien.

Typische Anwendungsfelder, in denen unsere gefertigten Flach- bzw. Flanschdichtungen aus Graphit zum Einsatz kommen, sind vor allem die Chemieindustrie bzw. Petrochemie, Gasversorgung, Raffinerien, Kraftwerke sowie Müllverbrennungsanlagen und Kesselhäuser. Sie alle vereinen hohe Anforderungen an Temperaturen genauso wie Beständigkeiten gegenüber aggressiven Medien und hohen Betriebsdrücken.

Graphit Dichtungen dienen zur Abdichtung von Rohrleitungen, Pumpen und Armaturengehäusen. Ebenfalls ist uns der Einsatz in Abgasleitungen bekannt.

Ob Graphit auch für Ihre Zwecke geeignet ist, beantworten wir Ihnen gern. Kontaktieren Sie dazu unseren Kundenservice, der Sie umfassend berät.